Filtered Cathodic Vacuum Arc

• FCVA is based on Cathodic Vacuum Arc

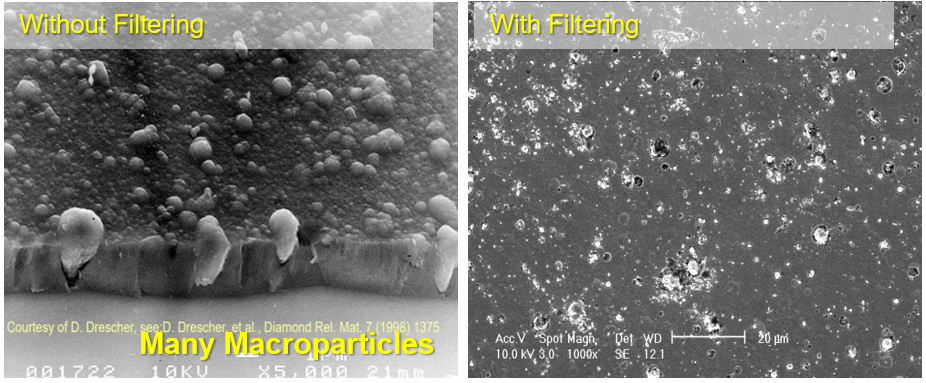

• Especially, it has a bent duct and electromagnetic coils

between cathode and workpiece in order to deposit smooth coatings

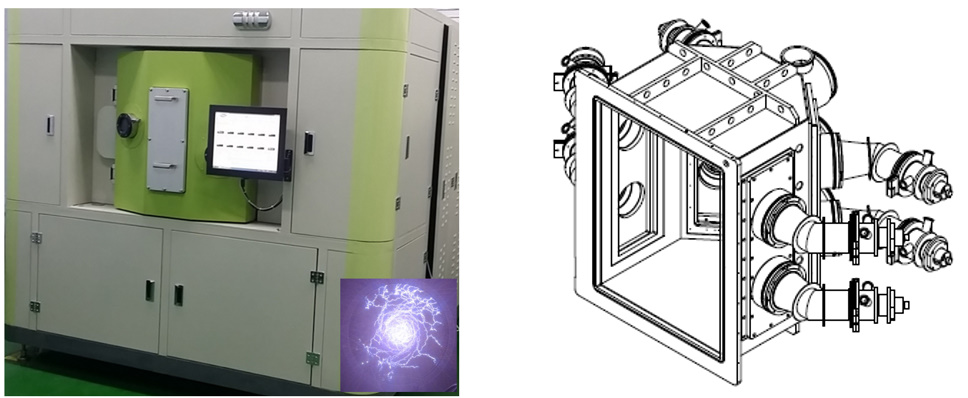

• Effective area : Φ450 x H400

• Deposition rate, 0.15 um/h per cathode with double rotation

• Etching source : Ion Gun •Buffer layer source : Sputter

• H Free DLC : FCVA gun x 4

• Pumping : R/P+MBP+Turbo Pump ~10-5 torr

• Heater : <250℃

ta-C Coating

● Tetrahedral amorphous Carbon

● Hydrogen free coating

● Higher sp3(diamond) bonding

● Hardest coating of DLC ,<80GPa (HV2,000~7,000)

● Thermal stability ,<500℃

● Low friction, 0.2@dry

● Typical thickness : <1um for tools , 1~10um for auto. parts