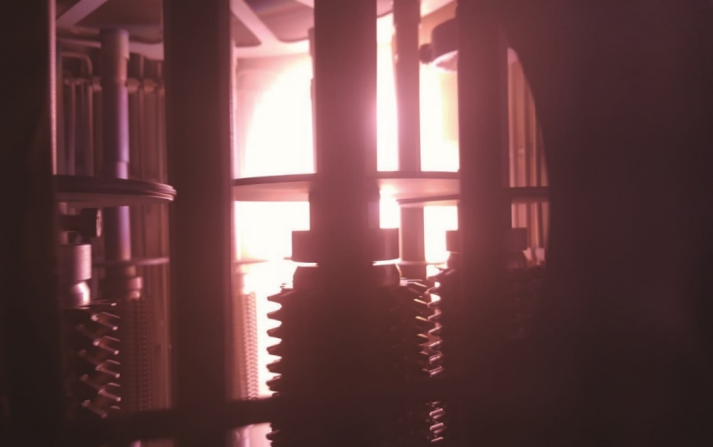

利用等离子体在蒸发源(Target)表面使用Arc、E-Beam、Direct heating等方式,将金属物质蒸发后,

施加Bias电压进行加速,在产品表面蒸镀物质的方法。

在真空500℃以下的低温状态下,物理蒸镀的工艺,涂层厚度仅为数千分之一毫米,比硬质合金强,并且化学性能稳定。

延长产品寿命、纺织腐蚀、防止磨损、减少粘连和摩擦,使生产效率最大化。同时,减少润滑油(离型剂)的使用量,

解决了表面处理的污废水问题,更加环保。

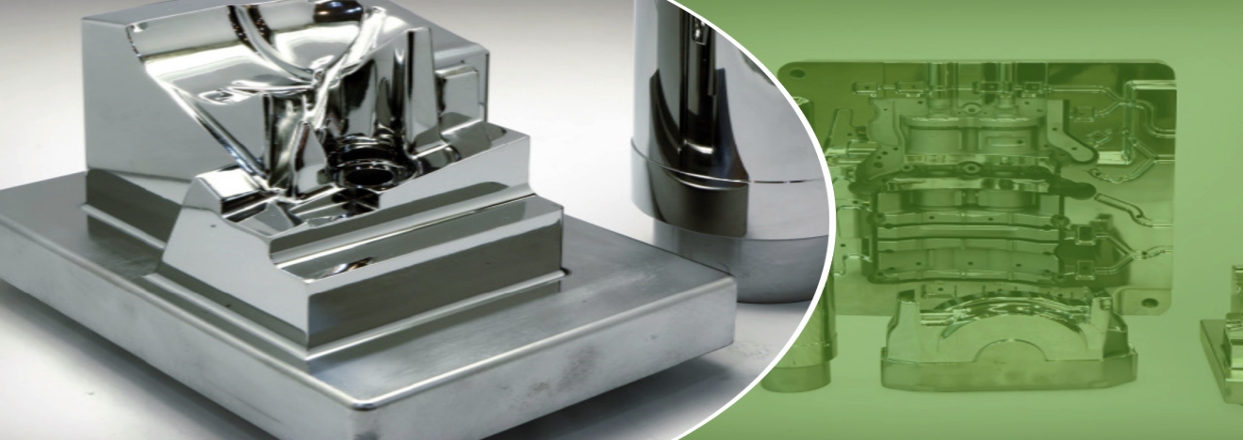

设备

| Division | Coating | Materials | Process | Properties | Features | Applications | ||||||||||

| Method |

Temperature (°C) |

Hardness (Hv) |

Friction C.O.F |

Thickness (um) |

Max Temp (°C) |

Color | Friction | Wear | Sticking | Thermal | Corrosion | Decorative | ||||

| Cutting | DURON-A | TiN | CA | 500 | 2,600 | 0.5 | 2-5 | 600 | Gold | ● | ● | ● | Tool, Mold | |||

| DURON-T | AlTi Based | CA | 500 | 3,300 | 0.5 | 2-5 | 900 | Gray | ● | ● | Tool | |||||

| DURON-H(S) | AlCr Based | CA | 500 | 3,200 | 0.5 | 2-5 | 900 | Blue Gray | ● | ● | Hob | |||||

| DURON-M | AlCr Based | CA | 500 | 3,200 | 0.5 | 2-5 | 900 | Blue Gray | ● | ● | Tool | |||||

| Forming | CrN plus | CrN nano | CA | 500 | 2,500 | 0.5 | 5-15 | 600 | Gray | ● | ● | ● | Cold forming | |||

| HEPHAIS | TiAlCr Based | CA | 500 | 3,100 | 0.5 | 5-15 | 900 | Gray | ● | ● | High tensile strength steel | |||||

| POLLUX | TiAlCrSi Based | CA | 500 | 2,900 | 0.5 | 5-15 | 1,000 | Gray | ● | ● | ● | ● | Die casting, forming | |||

| CA : Cathodic Arc, SB : Salt Bath, SP : Sputtering, PC : PACVD, IG : Ion Gun, FCA : Filtered Cathodic Arc | ||||||||||||||||